Full Length Research Article

Bioremediation of petroleum hydrocarbon contaminated soil by xylanase enzyme

Hassan Muslem Abdulhussein1*, Sahira Nsayef Muslim2, Wafaa Hassan Muslem2

Adv. life sci., vol. 12, no. 1, pp. 255-259, February 2025

*- Corresponding Author: Hassan Muslem Abdulhussein (Email: wafaahassan2017@uomustansiriyah.edu.iq)

Authors' Affiliations

2. Department of Biology, College of Science, Mustansiriyah University, Baghdad – Iraq

[Date Received: 19/01/2024; Date Revised: 25/08/2024; Date Published: 31/12/2024]

Editorial Expression of Concern:

18 May 2025: Following publication of this paper, the internal audit (consequent to concerns on quality raised by Web of Science) notified Advancements in Life Sciences about problems in use of English language. By this Editorial Expression of Concern, we alert the scientific community as we address the errors.

Editorial Note:

31 May 2025: You are viewing the latest version of this article having minor corrections related to the use of English language. Expression of concern is hereby revoked.

Abstract![]()

Introduction

Methods

Results

Discussion

References

Abstract

Background: The global spread of petrochemical and petroleum contamination, such as petroleum hydrocarbons (PHCs), is currently a significant environmental risk. The global biosphere is badly harmed by these pollutants, and biodiversity is significantly reduced. This study was to screen for xylanase synthesis in Pseudomonas spp. and evaluate its efficiency as a bioremediator in removal of hydrocarbons from hydrocarbon-contaminated soil.

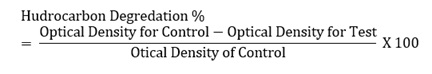

Methods: Soil samples from Al-Dora oil plant Baghdad, Iraq, were cultured in nutritional agar medium containing 0.5% of corn cob xylan for determination of xylanase producers and measuring of xylanase activity, after that xylanaseproducers were identified. The xylanase was purified with DEAE-cellulose chromatography and the percentage of hydrocarbon degradation was calculated after treatment of hydrocarbon-contaminated soil with purified xylanase and detection of hydrocarbon degradation percentage.

Results: Pseudomonas putida had the highest productivity for xylanase in comparison with other Pseudomonas species such as Pseudomonas syringae and Pseudomonas aeruginosa, which revealed lower levels in xylanase production. Ammonium salt saturation and ion exchange chromatography were used to purify the xylanase enzyme on a DEAE-cellulose column with ultimate recovery of 43% and 4.3 fold of purification. With pure xylanase, hydrocarbons degraded over time, peaking after two weeks and then progressively diminishing.

Conclusions: Pseudomonas putida is the best producer for xylanase than other species. The purified xylanase led to removal of hydrocarbons from hydrocarbon-contaminated soil in a time-dependent manner until maximum removal after 15 days. Authors recommend using xylanase for cleaning up of oil-contaminated areas. Therefore, employing microorganisms as biological tools may be a more feasible way to handle one of the most serious issues in modern society which might be a more workable and affordable way to minimize waste and preserve natural resources.

Keywords: Petroleum hydrocarbons; Pseudomonas putida; Xylanase; Bioremediation; Soil contamination

The contamination of soil with crude oil is a problem that affects the entire planet. Crude oil contains a variety of hazardous components with high toxicity and low biodegradability [1]. Furthermore, the hydrocarbon degraders in oil-contaminated soil are less active due to the presence of hazardous metals in petroleum [2].

The two varieties of gasoline-range hydrocarbons (GRHs) are gasoline-range GRHs and diesel-range GRHs. DRHs (PHCs) include, for example, polycyclic aromatic hydrocarbons and longer chain alkanes. GRHs include hydrocarbons such toluene, benzene, xylenes, and ethylbenzene [3]. Glycoside hydrolases called xylanases (EC 3.2.1.x) catalyze the endohydrolysis of 1,4-D-xylosidic links in xylan. A wide range of organisms, including bacteria, algae, fungi, protozoa, gastropods, and anthropods, produce this ubiquitous group of enzymes, which are involved in the formation of xylose, a key carbon source for cell metabolism, and in plant cell infection by plant pathogens [4]. The second-most prevalent polysaccharide in nature, xylan serves as a primary structural component in plant cells and makes up around one-third of the entire planet’s renewable organic carbon. The main ingredient of hemicellulose, xyloglucan, glucomannan, galactoglucomannan, and arabinogalactan is xylan [4, 5]. In brewing, xylanases can improve wort filterability and reduce haze in the final product. They can also be used in coffee extraction and the preparation of soluble coffee, detergents, the protoplastation of plant cells, the production of pharmacologically active polysaccharides for use as antimicrobial agents or antioxidants, and the production of alkyl glycosides for use as surfactants [6].

The aim of the current study was to extract xylanase from Pseudomonas putida, purify it and evaluate its efficiency as a bioremediator in removal of hydrocarbons from hydrocarbon-contaminated soil.

Collection of samples

from different locations around the Al-Dora oil plant, Baghdad, Iraq. 18 soil samples were taken. The soil samples were kept cool by placing in sterile polythene bags. In order to conduct additional studies, these samples were taken to the lab and kept there at 4°C.

Primary screening of xylanase production

A soil sample of 1 g was combined with 99 ml of distilled water, shaken for 30 min, and then allowed to settle for 30 min. From dilutions of 10-2 to 10-6, we made successively. To generate xylanolytic bacterial colonies, each sample was inoculated onto nutritional agar medium containing 0.5% of corn cob xylan and incubated at 30°C for 48 h. For the purpose of determining the location of the xylan hydrolyzing zone surrounding the bacterial growth on xylan agar plates, plates were stained with 0.1% Congo red solution and left for 1 hour. The plates were then washed with 1M NaCl for 15 minutes for zone analysis.

Identification of xylanase producers

Morphological and biochemical studies were run on the colonies that had already been created as explained by [7]. To confirm these isolates, the Vitek 2 technology is also used.

Secondary screening for xylanase production

The chosen isolates were cultured at 30°C for 24 hours after being infected with nutritional broth that had been supplemented with 5% corn cob xylan. After 30 minutes of centrifugation at 8000 rpm, xylanase activity was assessed.

Xylanase activity and protein content

The substrate solution was prepared by mixing 0.3M of phosphate buffer with 1% corncob xylan at pH 7. To create a 1mL reaction mixture, 0.5mL of the substrate solution and 0.5 ml of each bacterial supernatant were added to an assay tube. The reaction mixture was then incubated in assay tubes for 15 minutes in a water bath at 55°C. Following the incubation, 1.5mL of 3, 5-dinitrosalicyclic acid solution (DNS) was added to each test tube, and the reaction was stopped by boiling the tubes at 100 °C for 10 minutes. Each bacterial supernatant's release of reducing sugar during hydrolysis was quantified using an absorbance value at 540 nm. The amount of xylose released per milliliter of enzyme per minute [8] was used to calculate one unit (IU) of xylanase activity. Using a bovine serum albumin standard and the Bradford method with the absorbency measured at 595nm, protein content was determined [9].

Purification of xylanase

By making a few adjustments to the procedure described in [10], the xylanase was purified. The clear supernatant from centrifugation was then provided to DEAE-cellulose chromatography after the chosen isolate had been cultured on the optimal production medium and fractionated using ammonium sulfate at 20–70% saturation. The dialysis-concentrated active pooled sample was put onto sephadex G-150, which equilibrated before being eluted with 0.3M phosphate buffer at pH 7. L-xylanase activity and protein concentration for the obtained portions were noted.

Xylanase's removal of hydrocarbons from polluted soil

20 gm of hydrocarbon-contaminated soil was mixed with 40 millilitres of pure xylanase. As a control, distilled water was used in place of the xylanase, which was incubated at 30°C for 24 hours. After being centrifuged for 10 minutes at 6000rpm, the soil's created liquid solution was given back. Every three days, the same amounts of soil and toluene were combined to determine the amount of hydrocarbons in the soil after interaction with pure xylanase compared to the control. After centrifugation, the toluene with hydrocarbon dissolved in it was measured at 410um absorbance [10].

Xylanase production primary screening

According to figure (1), these isolates included 2 (28%) isolates from Pseudomonas syringae, 2 (28%) isolates from Pseudomonas aeruginosa, and 3 (54%) isolates from Pseudomonas putida.

Xylanase production secondary screening

In contrast to other isolates, the results showed that Pseudomonas putida1 had the highest productivity at 4.85U/ml (table 1).

The Xylanase activity and the protein content

Following centrifugation, the clear supernatant was fractionated with ammonium sulfate at various saturation percentages after Pseudomonas putida1 was grown in nutritional broth supplemented with 5% corn cob xylan. At 65% saturation, the highest xylanase activity (17.23U/ml) was achieved. Following dialysis, the concentrated sample was run through sephadex G-150 to recover three protein peaks, the third of which showed xylanase activity (figure 2). The ultimate recovery was 43%, and the sample had been purified 4.3 fold.

Xylanase purification

The outcomes from the purification stages of xylanase from Pseudomonas putida are listed in Table 2.

Xylanase's removal of hydrocarbons from polluted soil

Purified xylanase was incubated with hydrocarbon-contaminated soil, and the absorbency of toluene was measured after mixing. The results revealed that the hydrocarbons were degraded over time, reaching a peak after 15 days before gradually declining, as shown in figure (3). As a result, bioremediation has come to be known as an alternative method of cleaning up oil-contaminated areas. In this method, microbial colonies are crucial to the process, either through direct pollutant destruction or by interaction with other microorganisms that have been added.

Figures & Tables

The results in figure 1 showed that 7 isolates of Pseudomonas were found out of the 18 collected samples after cultivating hydrocarbon-contaminated soils on nutrient broth supplemented with 5% corn cob xylan and identifying the resulting colonies. The diameter of clear zones on agar plates varied between 13 and 24mm according to the qualitative screening for xylanase production, with Pseudomonas putida isolates showing the best productivity, as indicated in table (1). In order to select Pseudomonas putida isolates as the greatest xylanase producers. Several bacterial genera, including Pseudomonas, Acinetobacter, and Mycobacterium are just a few of the bacterial strains that have been found to be capable of breaking down petroleum hydrocarbons [7]. This ability is attributed to the presence of genes and enzymes that use chemical complexes found in petroleum as important energy sources. Because of the high molasses levels, Pseudomonas stutzeri, an enzyme that breaks down xylan to get nutrients, may not have been created by the bacteria. . Microbes typically prefer to use a simpler molecule when there are two or more sources of carbon in the medium [11]. Pseudomonas stutzeri demonstrated strong xylanolytic activity in a medium containing 2% (w/v) birchwood xylan and a temperature of 37°C; this was due to the release of the xylanase enzyme, which breaks down xylan in the liquid media [12]. The medium including xylan, glucose, and meat extract, which was further adjusted by adjusting the component concentrations, promotes the growth of Pseudomonas sp. XPB-6 [13].Through the use of ammonium sulfate fractionation, DEAE-Sepharose CL-6B, Toyopearl HW-50S, and Butyl-Toyopearl 650M column chromatography, an endo-1,3-beta-D-xylanase was isolated from the culture fluid of Pseudomonas sp. PT-5 [14]. The xylanase has showed homogeneity in the gel electrophoresis by following a methodical procedure for the isolation and purification of xylanase from Pseudomonas flu using the techniques (NH)2SO4 fractionation and Sephede x G100 gel column [15].

Numerous microbial cellulolytic enzymes are necessary for the complicated process of cellulosic material degradation [16]. Cellulose and hemicellulose can be broken down either chemically (with acids or alkalis) or enzymatically. In the industry, lignocellulose degradation has been accomplished via a number of acid hydrolysis processes using sulfuric or hydrochloric acid at various concentrations, temperatures, and pressures [17]. The depolymerization of the polysaccharide components into sugar monomers, which occurs during the breakdown of lignocellulosic materials, is a difficult process that calls for a variety of enzymes [10]. Cellulose is broken down into glucose monomers by enzymes referred to as cellulases [16]. The type and number of microorganisms present in contaminated environments directly affect the efficacy of the applied restoration approach. The availability of the free contaminant and its ability to permeate the organism’s membrane affect how quickly the pollutant can be absorbed by the microorganism once PHC removal has started [18].

Pseudomonas putida may be the most efficient xylanase producer than other species. Purified xylanase led to removal of hydrocarbons from hydrocarbon-contaminated soil. These findings can encourage use of xylanase as an alternative bioremediator for cleaning up oil-contaminated areas.

Acknowledgement

The authors thank Mustansiriyah University (www.Mustansiriyah.com) and Department of Radiology, Dijlah University College, Baghdad, Iraq, for the support to complete this study.

Author Contributions

All authors participated equally in completing this manuscript.

No conflict of interest

- Al-kaabi N. A maldi-tof study of bio-remediation in highly weathered oil contaminated soils. Journal of Petroleum Science Engeering, (2018); 3: 23-29.

- ChengM. Hydroxyl radicals based advanced oxidation processes (AOPs) for remediation of soils contaminated with organic compounds: a review. Chemical Engineering Journal, (2016); 5(2): 37-41.

- Babu MK, Pramod J, Ramteke W. Production of laccase from newly isolated Pseudomonas putida and its application in bioremediation of synthetic dyes and industrial effluents. Biocatalysis and Agricultural Biotechnology, (2019); 2: 333-338.

- Ali SS, Al Tohamy R, Xie R, El Sheekh MM, Sun J. Construction of a new lipase- and xylanase-producing oleaginous yeast consortium capable of reactive azo dye degradation and detoxification.Bioresour. Technology, (2020); 99: 38-43,

- Harris AD, Ramalingam C. Xylanases and its Application in Food Industry: A Review. Journal of Experimental Sciences, (2010); 1(7): 1-11.

- Samanta AK, Kolte AP, Senani S, Sridhar M, Jayapal N. A simple and efficient diffusion technique for assay of endo β-1,4-xylanase activity. Brazilian Journal of Microbiology, (2011); 42(4): 1349-53.

- Su SS, Lae KZ, Ngwe H.Isolation and Identification of Pseudomonas aeruginosafrom the Clinical Soil. University of Yangon Research Journal, (2018); 8: 271-275.

- Paul M, Nayak DP, Thato H. Optimization of xylanase from Pseudomonas mohnii isolated from Simlipal Biosphere Reserve, Odisha, using response surface methodology. Journal of Genetic Engineering and Biotechnology, (2020); 18: 81-87.

- Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein–dye binding. Aral Biochemistry, (1976);72: 248-49.

- Fuentes S, Barra BJ, Caporaso JG, Seegera M. From rare to dominant: a fine-tuned soil bacterial bloom during petroleum hydrocarbon bioremediation. Applied and Environmental Microbiology, (2016); 82(3): 888-896.

- Lalucat J, Bennasar A, Bosch R, Valdes EG, Palleroni NJ. Biology of Pseudomonas stutzeri, Microbiology and Molecular Biology Reviews, (2016); 70(2): 510-547.

- Purkan SP, Huruniawati E, Sumarsih S. Xylanase Enzyme From A Local Strain Of Pseudomonas. Journal of Chemical Technology and Metallurgy, (2017); 52(6): 1079-1085.

- Sharma PK, Chand D. Production of cellulase free thermostable xylanase from Pseudomonas sp. XPB-6. International Research Journal of Biological Sciences, (2019); 1(5):31-41.

- Yamaura I, Matsumoto T, Funatsu M, Mukai E. Purification and some properties of endo-1,3-beta-D-xylanase from Pseudomonas sp. PT-5. Agriculture and Biological Chemistry, (1990); 54(4): 921-6.

- Yuping S, ShuhanW, Kai O. Purification and Properties of Xylanase from Pseudomonas flu. Journal of Nanjing Forestry University, (2009); 20 (2): 60-62.

- Kunle ZM, Nwodo UU, Mabinya LV, Okoh AI. Optimization of Cellulase and Xylanase Production by Micrococcus Species under Submerged Fermentation. Sustainability, (2016); 8(11): 1168-72.

- Gomez F, Sartaj M. Field scale ex-situ bioremediation of petroleum contaminated soil under cold climate conditions. International Biodeterioration and Biodegradation, (2013); 85: 375-382.

- Santos JVO, Ferreira YLA, Silva LLS, de Lyra IM, Palácio SB, Cavalcanti IMF. Use of bioremediation for the removal of petroleum hydrocarbons from the soil: an overview. International Journal of Environment, Agriculture and Biotechnology (IJEAB), (2018); 3(5): 1831-1838.

This work is licensed under a Creative Commons Attribution-Non Commercial 4.0 International License. To read the copy of this license please visit: https://creativecommons.org/licenses/by-nc/4.0![]()